國博工業有限公司

Auto-Way Casting IndustriesSINTAI CORPORATION

Autoway-Casting 於 1988 年在台灣成立。Autoway-Casting 是一家為不同終端市場生產高精度、高複雜性和關鍵任務的鑄件和機加工部件的製造商。 我們為多元化的全球客戶群提供定制鑄造和機加工產品,並提供表面處理服務。 我們的優勢地位源於我們的綜合業務模式以及為客戶提供一站式解決方案的綜合能力。

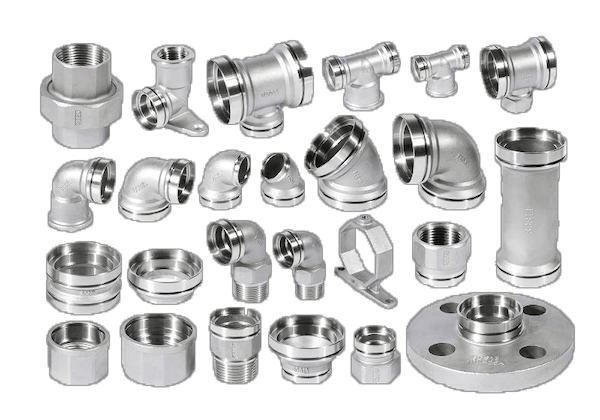

- 熔模鑄件

Investment Casting

1、工藝:我們具有完全整合的熔模鑄造工藝能力,涵蓋模具設計和制造、鑄造、熱處理、後道機加工和表面處理。

2、設備:我們在熔模鑄造過程的各個階段均采用最先進的技術和尖端的設備。模具設計、壓蠟、蠟模組樹、制殼、澆註、熱處理和測試均由我們專業的團隊使用最佳配置的設備來完成。

3、材料:我們能夠滿足ASTM、SAE、AISI、ACI、DIN、EN、ISO和GB等各種材料規範的要求。我們可以鑄造超過100種不同的黑色和有色合金,還可以滿足客戶提出的特殊材料要求。

1、Process Introduction:Auto-Way Casting has fully integrated investment casting process capabilities, ranging from tooling design and manufacturing, casting, heat treatment, secondary machining, and surface treatment.

2、Equipment:At Auto-Way Casting, we employ the latest in advanced technology and cutting-edge process equipment at various investment casting process phases. Tooling design, wax pattern injection, wax pattern assembly, shell-making, pouring, heat treatment, and testing are all performed using the best available machinery, operated by our qualified team of experts.

3、Materials:Auto-Way Casting is capable of meeting material specifications according to ASTM, SAE, AISI, ACI, DIN, EN, ISO, and GB standards. We cast more than 100 different ferrous and nonferrous alloys.

- 精密機加工

Precision Machining

1、工藝介紹:精密機加工通常需要進行計算機數控CNC編程,從多維度將特定的設計轉換成精確的形狀。精密機加工零件通常提供給整機制造商和系統集成商,成品零件用於廣泛的最終市場領域。

2、設備:我們使用高質量的加工設備來滿足全球客戶的需求。我們為醫療、汽車、液壓、石油和天然氣行業的各個領域的客戶提供廣泛的精密加工解決方案。

3、材料:我們根據行業和客戶規範加工各種材料,包括碳鋼、合金鋼、不銹鋼和鋁合金。

4、能力:我們因優質的產品和服務、合理的成本和及時交付而得到客戶的認可。我們通過了ISO 9001、TUV等高端資質認證。我們具有靈活而敏捷的生產運營能力,可滿足從幾件到幾萬件的訂單交付數量。

1、Process Introduction:Precision machining often requires the programming of computer numerical controls, or CNC, which allows for converting unique designs into exact shapes through multiple dimensions. Precision machined components are supplied to OEM customers and system integrators for diverse end-markets.

2、Equipment:Auto-Way uses high-quality processing equipment to satisfy the needs of customers around the world. Catering to sectors ranging from the medical, automotive, hydraulic, and oil and gas industries, Auto-Way provides a wide array of precision CNC machining solutions to our customers.

3、Materials:We process a wide variety of materials ranging from carbon steel, alloy steel, stainless steel, aluminum alloys according to industry and custom specifications.

4、Capabilities:Auto-Way takes pride in providing our high-quality products and services, reasonable costs, and timely delivery of all our products. We hold quality certifications according to ISO 9001, ISO/IATF 16949, AS 9100, ISO14001, and BS OHSAS 18001. Auto-Way is reputed for its flexible and agile manufacturing operations by delivering orders for just a few pieces or up to tens of thousands.

- 表面處理

Surface Treatment

1、工藝介紹:表面處理通常是壹種指通過改變工件表面以增強其外觀或性能的工藝過程。在鷹普,表面處理通常是指電鍍,電鍍是最廣泛使用的表面處理技術之壹,可提供多樣的金屬鍍層並具有很高的成本效益。

2、能力:我們提供全方位的電鍍和金屬表面處理服務。我們的工藝能力包括金屬制品的鍍鉻、鎳、鋅鎳、鎘、銅、鋅、錫鋅、鋅鐵、化學鍍鎳、陽極氧化、化學膜、鈍化、磷酸鹽和電拋光等。

1、Process Introduction:Surface treatment generally refers to a process to alter an object’s surface to enhance its appearance or functional properties. At Auto-Way, surface treatment refers to electroplating, one of the most widely used surface treatment techniques that provide broad coverage of coating metals and high cost-efficiency.

2、Capabilities:Auto-Way is a full-service electroplating and metal finishing provider. Our process capabilities include Chrome, Nickel, Zink-Nickel, Cadmium, Copper, Zinc, Tin-zinc, Zinc-iron, Electroless Nickel plating, Anodizing, Chem-Film, Passivation, Phosphate, and Electro-polishing for products made of carbon steel, stainless steel, aluminum alloy, and superalloys. Besides, we offer non-electrolytic coating services. We serve customers in the automotive, marine, high-speed rail, energy, superconductor, and medical industries.